| Cnc automatic turning | Rapid prototyping process | Cnc Prototype Machining |

| Cnc milling engraving | Peek machined parts | Titanium Cnc Machining |

| Cnc Milling Process | Cnc Manufacturing | custom cnc milling parts |

| Item | Specification |

| Material | Aluminum Alloy:5052 /6061/ 6063 / 2017 / 7075 / etc. |

| Brass Alloy:3602 / 2604 / H59 / H62 / etc. | |

| Stainless Steel Alloy:303 / 304 / 316 / 412 /316/212/316/SUS400, etc. | |

| Steel Alloy:Carbon Steel / Die Steel / etc. | |

| Other Special Materials::Bronze/ Copper alloys/ Lucite / Nylon / Bakelite / Non Metallic Material Parts etc. | |

| We handle many other type of materials. Please contact us if your required material is not listed above. | |

| Surface Treatment | Nickel plating. Zinc plating, Chrome plating, EDM, Black, Nitrogenation. |

| Machining Equipment | 4-axis CNC Machining Center, CNC Lathe, High Speed Electric Spark Puncher, Milling Machine ,Grinding Machine, CNC Lathes , Wire-cuts , Laser Cuts , CNC Shearing Machines ,CNC Bending Machines, etc. |

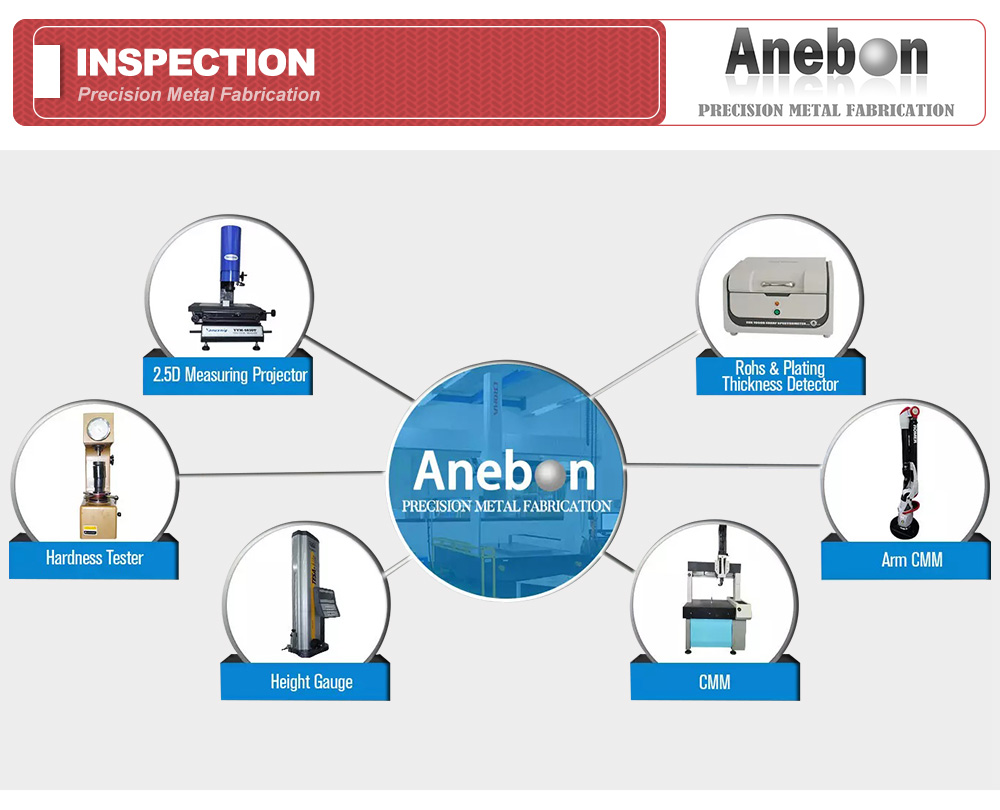

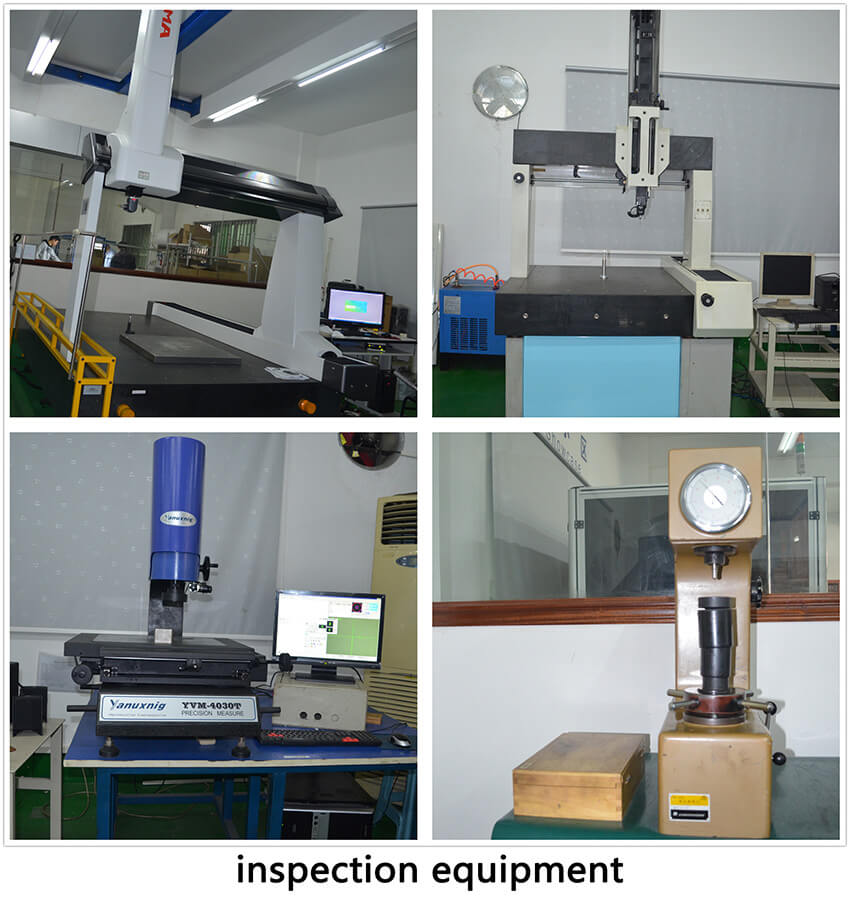

| Quality Control and Detection Equipment | Our QC department work is inspection and final inspection. We promise you as below:1. Check the raw material before the production..2. Have inspection during the production.3. Make 100% inspection before the shipment. Coordinate Measuring Machine, Calipers, Microscope, Micrometer, DEM, Height Meter and 00 Level Marbel Panel, Ring Gauge, Three Pin, Thread Gauge. |

| Quality Assurance | ISO9001:2015 |

| Production Output | Based on customer's drawing or samples. Usually 300.000 pieces/ month. |

| Experience | 10 years of professional; OEM service |

| Lead Time | Usually based on customer's drawing or samples. |

| File Formats | Pro/Engineer, AutoCAD(DXF,DWG), PDF, TIF , UG, Mastercam , Caxa, Pull mill, etc. |

| Shipment | Deliver out by DHL,FEDEX Or according to customers' requirement |

| Advantage | Competitive price, Near pot, experienced engineers, custom service |

.jpg)